Alberta is well known for its oil. The Western province is in fact the largest producer of crude oil in the Canada[i]. The source of the oil is bitumen, which is refined into other products, such as petroleum and fuel. The oil extraction process can leave equipment coated inbitumen residue, which is similar in texture to molasses. Left in place, the residue can quickly inhibit the efficiency of production equipment and electrical components, and can also reduce the duty cycle of equipment.

Bitumen residue becomes extremely hard when it sets, making removal one of the most challenging issues for plant operators. Unfortunately, traditional methods of cleaning bitumen from production equipment can be labour intensive and damaging to the equipment; often involving grinding and chipping the bitumen from the surface and removing the residue with a wire brush. Even high-pressure power washing is problematic because it produces a secondary waste and can only be carried out in spring or summer due to Alberta’s sub-zero temperatures in winter, which can cause the water to freeze on the equipment.

Operating from Fort McMurray, Western Dry Ice Blasting has extensive experience carrying out cleaning projects in the Alberta oil sands. Dry ice blasting is an ideal solution for removing bitumen residue, as it’s a non-abrasive, completely dry method that leaves no secondary waste. Using a fully portable and self-sufficient dry ice blasting unit, requiring no power source, Western is able carry out cleaning projects with little to no disruption to production.

Here are a few examples of the bitumen cleaning projects that Western Dry Ice Blasting carries out in the Alberta oil plants:

Roller bearings on conveyor systems

Roller bearings on conveyor systems carrying material for refinement quickly build up with residue, making it difficult for maintenance, repair or replacement work to be carried out to the bearings.

Western Dry Ice Blasting’s cleaning process removes the bitumen from the bearings in a fraction of the time as alternative cleaning methods, with no secondary waste. This allows the plant millwrights to repair, or remove and replace the bearings quickly, lessening production downtime.

Electrical and instrumentation panels

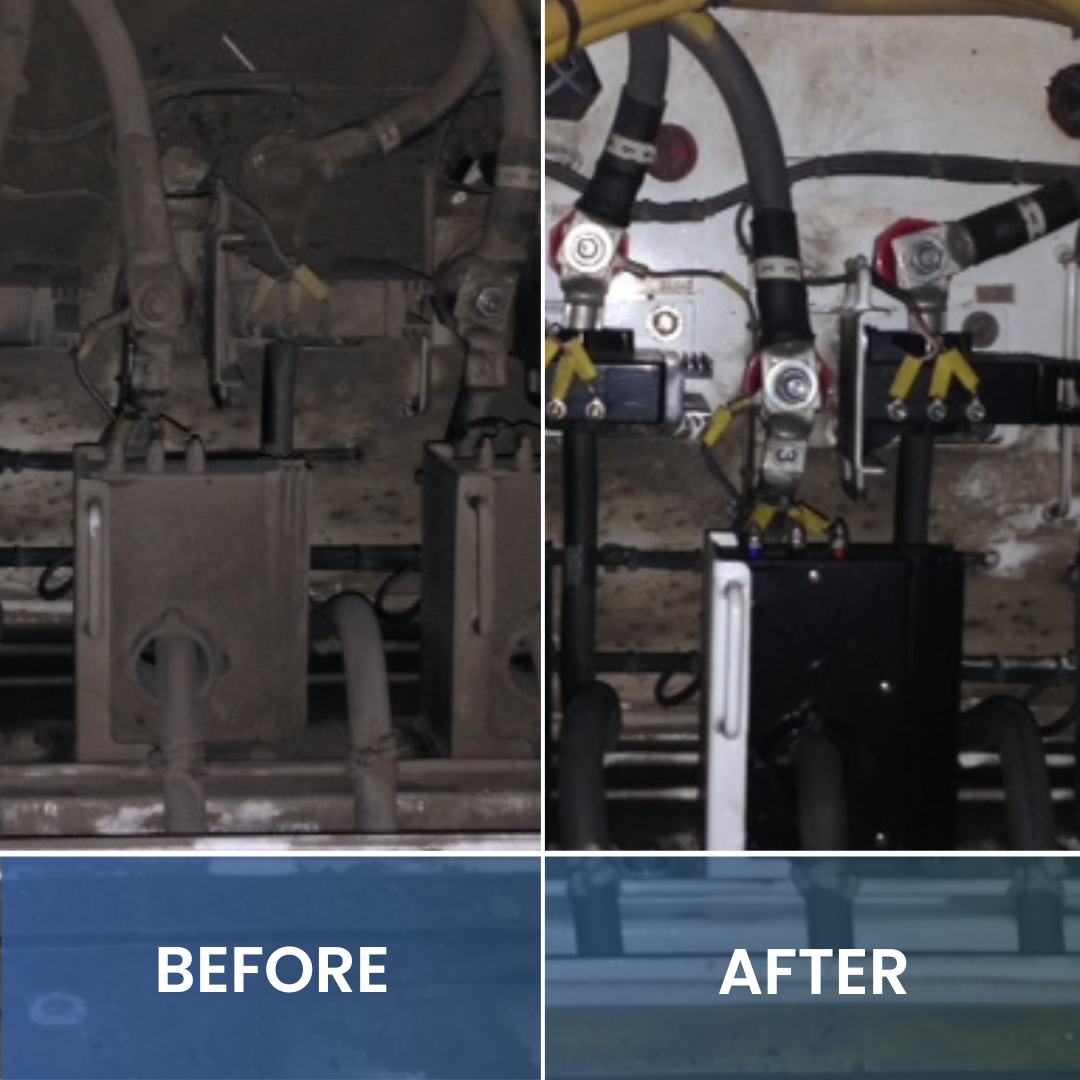

As oil refinement is carried out, electrical panel covers become coated in bitumen residue, making it difficult for Instrumentation and Electrical (IE) personnel to access the electrical panel. The inside of the panel can also become built up with residue and other foreign materials, coating the wiring and components, which can be a problem when trying to carry out maintenance work.

The dry ice blasting process, being completely safe on the switches, wiring and internal components of electrical panels, is the ideal solution for cleaning both the outside covers and the inside of the panels. Cleaning the panels facilitates timely repairs and maintenance work and enables IE personnel to identify the proper colour coding of the wiring.

Electric motors

Electric motors on crusher and conveyor systems carrying material for refinement become plugged with residue and production debris in the cooling fins, which can reduce the lifespan of the motor due to overheating. Western Dry Ice Blasting is able to carry out, in situ, cleaning the fins on electrical motors. This allows for easy maintenance of the motor, and promotes cooler operating temperatures, extending the life of the motors by up to 50%.

Call us today to learn more about how Western Dry Ice Blasting can help lower your maintenance costs, extend your equipment lifespan, and keep your production processes running smoothly.