Techniques Used: Dry Ice Blasting

Techniques Used: Dry Ice Blasting

Service: Bitumen Removal

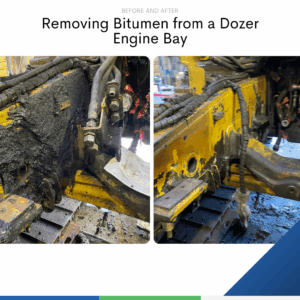

Dozers that work in tailings ponds face some of the harshest conditions in oil sands operations: sitting in water, sludge, and accumulating bitumen tar across all surfaces while they work.

When one such dozer was due for an engine change, the buildup it had accumulated made the unit inaccessible. Bitumen had hardened over key components, blocking access to mechanical fasteners and presenting both fire and safety risks. Instead of pausing for days of chemical cleaning or manual scraping, the client turned to dry ice blasting.

The Situation

At a remote oil sands operation in Northern Alberta, a large, tracked D8 dozer was preparing for an engine replacement after months of heavy service in extreme conditions. The dozer had been operating in tailings ponds, where it frequently worked submerged in water and sludge, with bitumen rising well past the tracks and often up to the cab.

This consistent exposure to water, sludge, and hydrocarbon-rich tailings left the engine bay coated in thick layers of hardened bitumen. The build-up was dense, black, and baked into nearly every surface: wiring harnesses, hydraulic lines, fasteners, and critical mounting points.

Before technicians could begin installing the new engine, the entire engine compartment needed to be thoroughly cleaned. Access to fasteners and components was obstructed, and the presence of bitumen posed both a mechanical and a safety hazard. Standard cleaning methods like chemical soaking or manual scraping would have been too slow, labour-intensive, and risked damaging sensitive parts or contaminating the worksite.

The client needed a solution that was fast, clean, and effective: capable of removing layers of bitumen without adding new risks to the operation.

The Solution

To meet the tight maintenance timeline and avoid downtime, the client brought in Western Dry Ice Blasting to perform an on-site engine bay cleaning. The job required precision and a cleaning method that could cut through heavy bitumen buildup without damaging underlying components.

Our team used dry ice blasting for this project. This non-toxic cleaning method, suited for oil sands equipment, involves blasting dry ice pellets at high velocity, which instantly freezes and fractures bitumen on impact, causing it to break away from surfaces without damaging paint, hoses, wiring, or sensitive electrical fittings.

The entire job was completed in a single shift by a compact crew of two: one technician and one supervisor managing on-site safety and coordination. The dozer remained parked in its staging area, avoiding the need for transport or disassembly. Using mobile dry ice blasting equipment, we targeted buildup in the engine compartment while maintaining full visibility and control over the cleaning.

Because dry ice sublimates on contact, there was no secondary waste to dispose of, so the site stayed clean and compliant through the entire process.

Within hours, the engine bay was stripped of bitumen buildup, exposing clean surfaces, mounting points and mechanical components – allowing the client clear access to complete the engine swap.

The Results

The outcome was exactly what the client needed: a thoroughly cleaned engine bay, ready for mechanical work, completed in one shift without disrupting operations or using additional resources.

The client avoided a multi-day cleanup, minimized risk to their equipment, and eliminated the need for chemical handling or multi-person scraping crews.

Need Precision Cleaning Fast?

Whether you’re preparing for an engine swap or dealing with heavy bitumen contamination from tailings operations, Western Dry Ice Blasting delivers fast, equipment-safe cleaning that gets the job done right, on-site and on schedule.

With mobile crews, 24/7 availability, and a proven track record in oil sands environments, we help maintenance teams stay on track, reduce downtime, and eliminate the risks that come with chemical or abrasive methods.

Contact us today for more information on how dry ice blasting can effectively clean bitumen residue and buildup from your equipment.