Techniques Used: Dry Ice Blasting

Service: Fire Restoration

When an e-house fire occurs, it can lead to unplanned downtime – a potential disaster for anyone in the oil industry. Businesses need to be able to turn to a company that can clean the areas quickly, effectively, and safely so repairs can be made and operations can be brought back online as soon as possible.

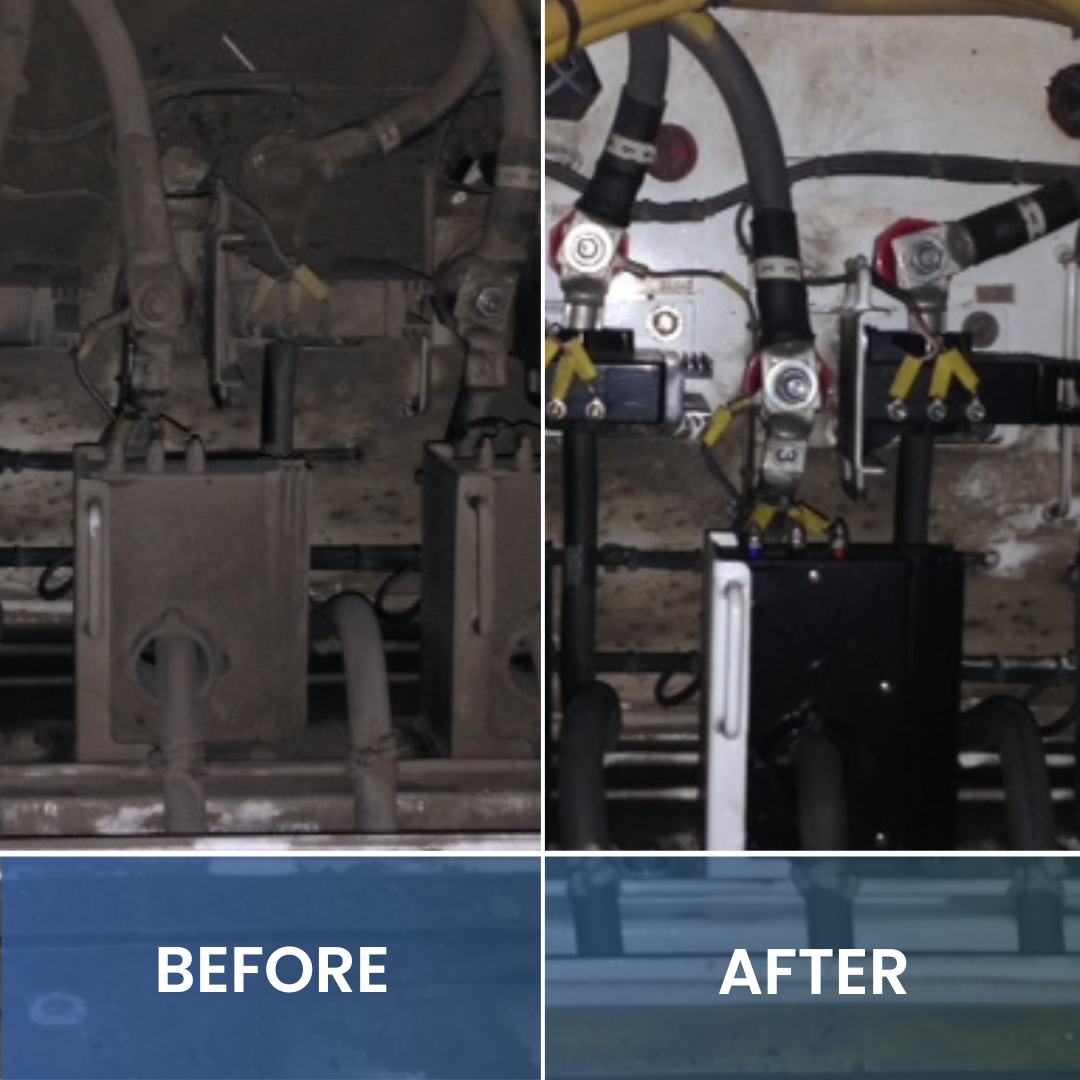

At Western Dry Ice Blasting, we are experts in performing e-house fire restoration and electrical cleaning. Our dry ice cleaning method removes the residue and soot caused by fire and smoke safely, removing them without damaging the delicate and hard-to-reach areas across the many precise components.

The Situation

Western was contacted by a local electrical engineering company to complete a fire cleanup at an oil sands site after a fire had broken out in one of their e-houses. A switch had malfunctioned in their e-house and led to a flashover, causing smoke and soot to contaminate the entire building. The fire also caused a strong odour due to the smoke that filled the area.

Smoke residue and soot had settled on all the equipment, including switches, panels, cable trays, and the building structure. The client needed the residue and smell to be removed quickly so they could repair the e-house and return to operations. This e-house, however, was within an isolated area of the client’s mines and could be hard to reach without the right vehicle.

The major concerns of this project were the delicate nature of the e-house’s electrical components and the small spaces where soot had collected within the cable trays and other areas. The client needed these areas cleaned safely without any damage as quickly as possible.

The Solution

In time-sensitive or emergency situations, Western can respond and mobilize to sites within 24 hours. Due to the urgency of this situation, we were able to put together a team and arrive on-site to perform this restoration in under 24 hours.

In time-sensitive or emergency situations, Western can respond and mobilize to sites within 24 hours. Due to the urgency of this situation, we were able to put together a team and arrive on-site to perform this restoration in under 24 hours.

We chose dry ice blasting to clean and restore this e-house. Dry ice blasting is a non-conductive cleaning method that safely and effectively removes dust, dirt, and debris from hard-to-reach areas while remaining delicate to prevent any damage.

While the e-house was in a difficult-to-reach area, Western’s trucks are suitable for travelling into the mines and other challenging areas. This meant our team and equipment could travel safely to the e-house without concern.

Once we arrived, our team of two technicians worked quickly, using dry ice blasting from the top down to remove the residue and soot effectively. We used our machines at a low pressure to remove soot from delicate areas like switches and wiring and ensured we used precise blasting nozzles to easily clean hard-to-reach areas that hand cleaning would struggle with.

As repairs were being made while we cleaned, we ensured that we cleaned in a way that prevented cross-contamination. This helped prevent re-work and ensured repairs could be made to the electrical systems quickly.

The Results

Our team was able to complete the restoration and cleanup of the e-house for the client in 2 days, allowing them to finish repairs and return to work quickly.

The client was pleased with the work completed, and the speed that we arrived on site and completed the cleaning for them. We look forward to working together to support any of their needs in the future.

Serving Fort McMurray

As a local company serving the greater Fort McMurray area, Western Dry Ice Blasting is a strong advocate of environmentally safe, non-conductive cleaning methods.

Contact us today for more information on how dry ice blasting can effectively clean smoke and fire residue from your site.