Techniques Used: Dry Ice Blasting

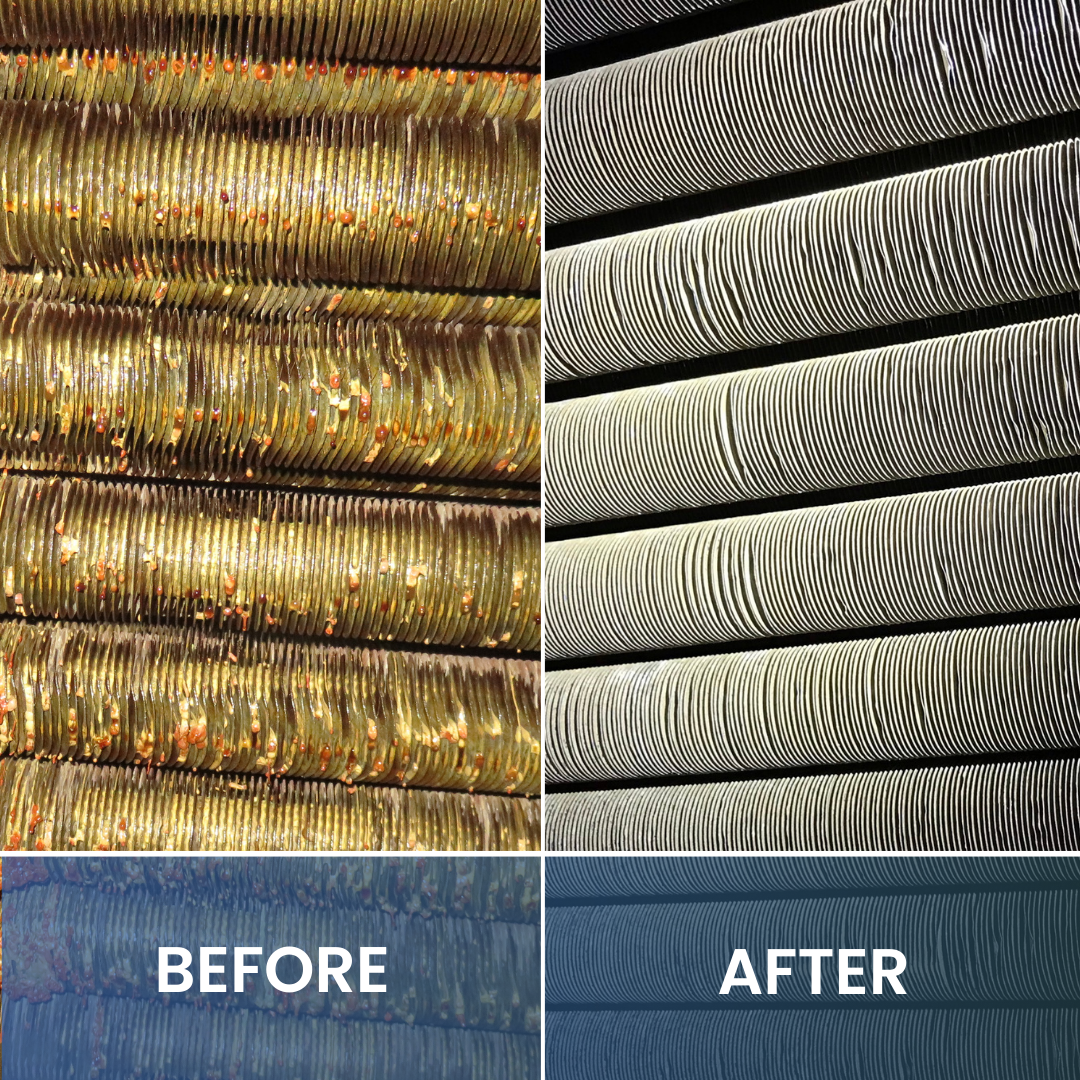

Service: Fin Fan Cleaning

Maintaining operational reliability and efficiency in industrial equipment is critical to running a strong business in the oil and gas industry. For business owners, the stakes are high: operational downtime not only delays productivity but also impacts profitability.

This case study highlights a proactive approach to equipment maintenance taken in early spring by one of our clients, a key player in the oil and gas industry, focusing on the preventive cleaning of fin fan coolers across four separate plants.

The Situation

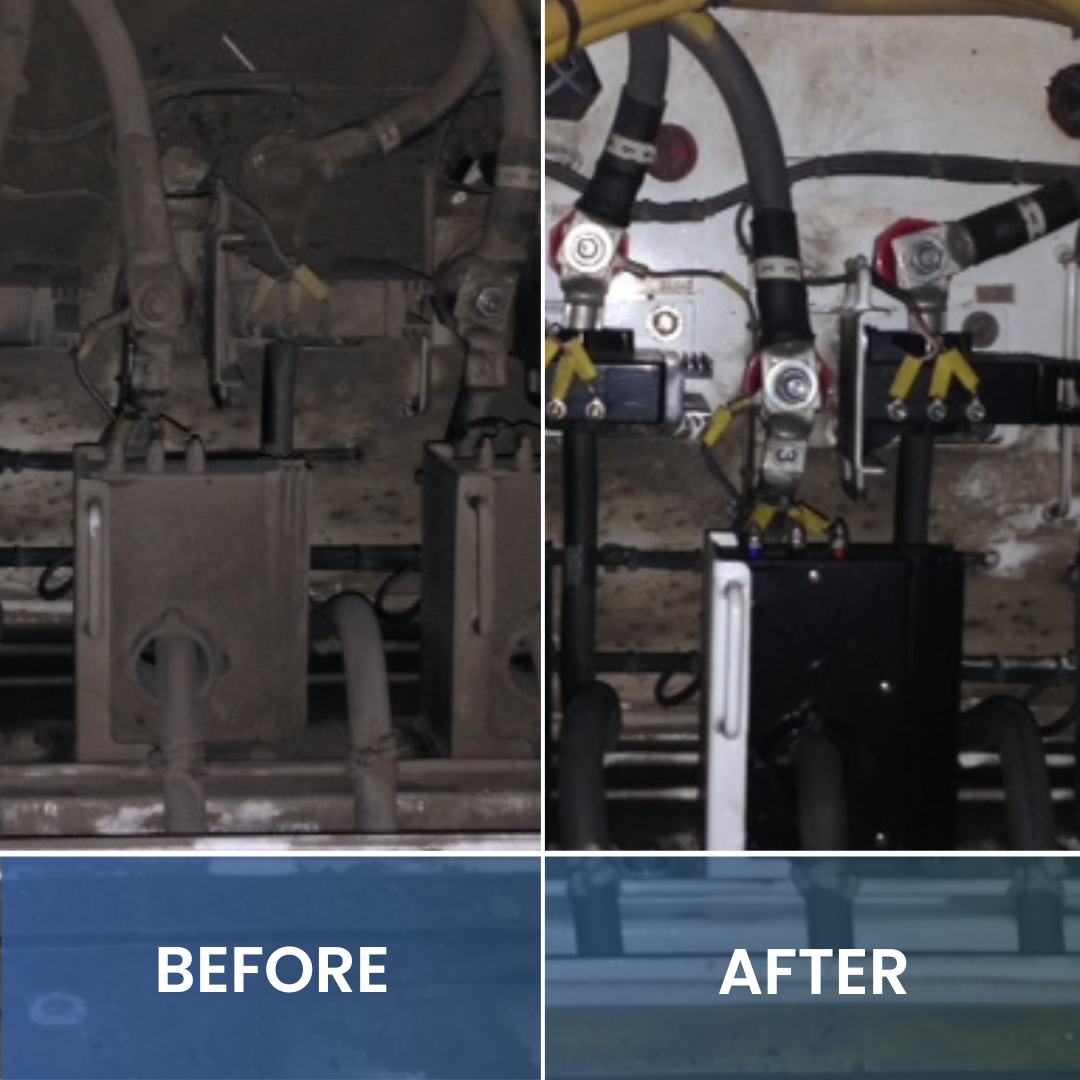

The Western team was called in early spring by a client who was proactively planning the maintenance needs of their oil sands plants. They were looking to prevent overheating and potential downtime in the hot summer months, and wanted us to perform cleaning on their fin fans.

Our task was to perform dry ice blasting on a total of 25 fin fan coolers, ensuring each unit would operate at peak efficiency when needed.

The Solution

Within 48 hours of receiving the call, our team was mobilized and ready to address the client’s needs. We adapted our timeline to accommodate our client’s schedule and operational requirements, coordinating closely to ensure our arrival and cleaning processes were seamlessly integrated into their plant activities.

This timeline included scheduling the work during night shifts to ensure minimal disruption to our client’s operations. Each shift was staffed with a skilled crew comprising of a project manager and three technicians, strategically working to clean the fans one at a time to ensure efficient cooling was still possible.

Given the location of the fin fans, situated five to six floors up within the plants, we utilized cranes to safely and efficiently hoist all necessary equipment for the job.

Dry ice blasting is unparalleled in removing contaminants, dust, and buildup without harming the delicate fins. By penetrating deep into the tube banks, dry ice blasting clears out years of debris without leaving secondary waste, resulting in temperature reductions of up to 30%. This technique not only preserves the integrity of the fin fans but also prevents corrosion that could be induced by moisture from other cleaning methods.

Dry ice blasting is unparalleled in removing contaminants, dust, and buildup without harming the delicate fins. By penetrating deep into the tube banks, dry ice blasting clears out years of debris without leaving secondary waste, resulting in temperature reductions of up to 30%. This technique not only preserves the integrity of the fin fans but also prevents corrosion that could be induced by moisture from other cleaning methods.

Our approach allowed us to conduct thorough cleaning without requiring a shutdown, maintaining operational continuity for our client.

The Results

Our dedicated efforts culminated in the successful cleaning of all 25 fin fans across four plants within a single month. This timely completion meant that our client could confidently kick off their summer operations.

The client expressed satisfaction with the quality of our work and was particularly pleased with the prospect of enhanced equipment longevity and performance following our thorough cleaning. The positive outcome of this project not only ensured operational efficiency but also reinforced the trust and reliability between our client and Western Dry Ice Blasting.

Our client also expressed enthusiasm about continuing our partnership, looking forward to working with us again for future maintenance needs.

Serving Fort McMurray and Beyond

As a local company serving the Fort McMurray area and Alberta, Western Dry Ice Blasting strongly advocates environmentally safe, non-conductive cleaning methods.

Contact us today for more information on how dry ice blasting can effectively clean smoke and fire residue from your site.